Networking

In modern industrial automation, networking refers to the communication infrastructure that connects all components of a control system — such as PLCs, HMIs, sensors, actuators, SCADA, and field devices — allowing them to exchange data and work as an integrated, intelligent system.

- Purpose

- Protocols

- Components

- Applications:

- Benefits

Data exchange between controllers, devices, and operator stations Remote monitoring and control of processes Real-time communication for closed-loop control Integration of multi-vendor devices using common protocols Scalability and expansion of control architecture

thernet/IP: Rockwell/Allen-Bradley systems; high-speed and scalable

PROFINET:Siemens-based automation; supports real-time and IRT

Modbus RTU/TCP Serial / Ethernet Widely used, open protocol; simple and robust

DeviceNet:Used for sensors and actuators in Rockwell systems

Profibus:Siemens field communication; DP for fast devices, PA for process instrumentation

OPC: Integrates PLCs, SCADA, and MES/ERP systems

HART:Superimposes digital data on analog 4–20 mA signal

BACnet:HVAC and building automation systems

WirelessHART / ISA100:Remote sensors, hard-to-wire environments

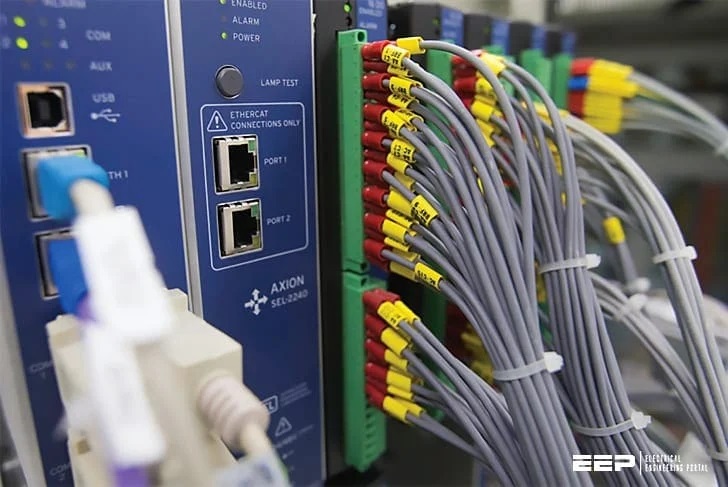

Switches & Routers: Industrial-grade for Ethernet connectivity

Gateways: Bridge between different protocols (e.g., Modbus to OPC)

Firewalls: Protect control networks from unauthorized access

Access Points: For wireless sensor networks

Remote I/O Modules: Extend inputs/outputs across networks

Connecting PLCs and SCADA in factory automation

Integrating remote sensors and actuators in water/wastewater plants

Linking building systems (HVAC, lighting, security) in smart facilities

Enabling predictive maintenance through cloud-based analytics

Real-time visibility and control

Centralized data logging and analytics

Reduced wiring and installation costs

Flexibility to scale and upgrade systems

Increased uptime and process reliability